Metallurgical Test Work: Gold Processing Options, Physical ...

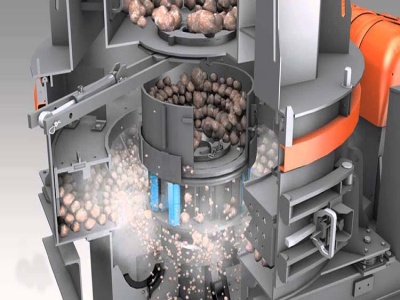

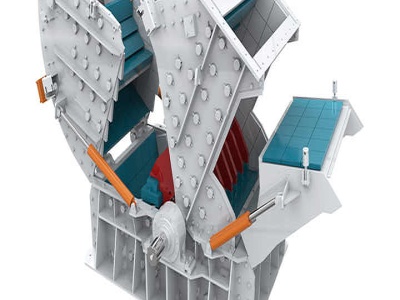

· 1. Background. For the past 100 years, the key element in the processing of gold ore has been the cyanidation the years, steady improvements have occurred in equipment design; milling has evolved from stamp mills, through tube mills and ball mills to the large semiautogenous grinding (SAG) and fully autogenous grinding (FAG) circuits in modern .

![[PDF] The Effect of Increasing Capacity on Gold Recovery ...](/um7yinb/998.jpg)

![[PDF] The Effect of Increasing Capacity on Gold Recovery ...](/um7yinb/489.jpg)

![[PDF] The Effect of Increasing Capacity on Gold Recovery ...](/um7yinb/1337.jpg)

![[PDF] The Effect of Increasing Capacity on Gold Recovery ...](/um7yinb/1367.jpg)