Fuel and Energy Research Forum

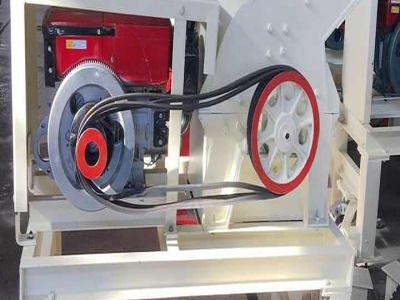

– Conveyors – Mills – PF systems – Burners and furnace – Air heaters – Draught plant • Not an exhaustive list – all plants are different • For this presentation, we will focus on combustion safety issues, principally the boiler. FERF Annual Meeting 26 April 2017 4 Definitions Hazard and Risk • Hazard – anything that can cause harm • Risk the chance, high or low ...