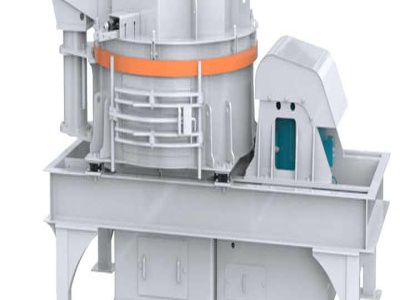

Laboratory Mills

The feed is at one end of the cylinder and the discharge is at the other. Small versions of ball mills can be found in laboratories where they are used for grinding sample material for quality assurance. Operation of a ball mill: Laboratory Sample Mill. Sample Mill are designed for grinding particularly hard dry materials, they are similar to coffee grinders but they are more powerful and a ...