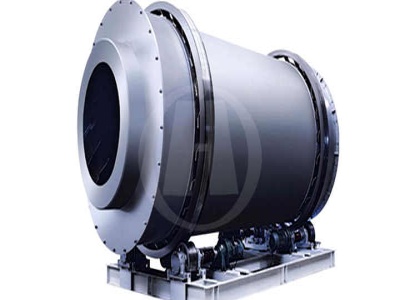

HOW BALL MILL WORKS?

· The ball mill is a hollow drum closed with loading and unloading end caps, filled with grinding media and rotated around its drum of the ball mill (Pic. 1) is a hollow cylinder of steel, lined inside with armor lining plates which protect it from impact and friction effects of the balls and the grinding material.