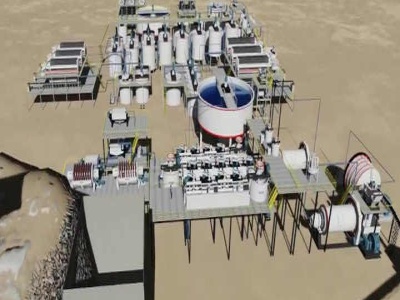

Copper Extraction Process

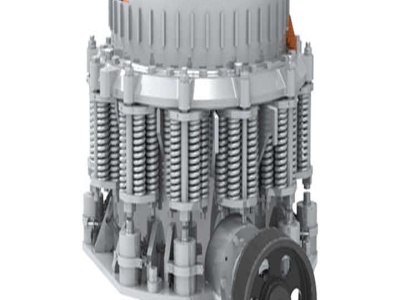

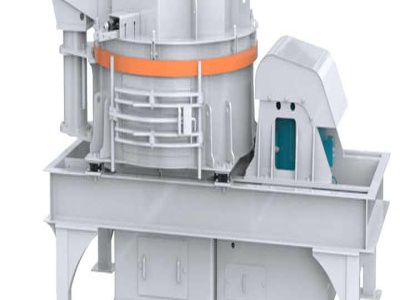

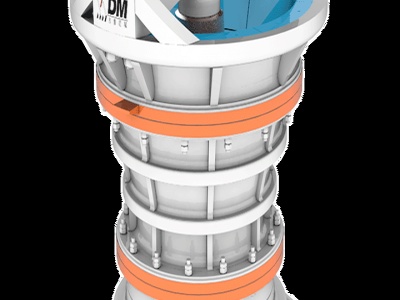

The process flow is Crushing > Screening > Grinding > Concentration. Description: The whole copper processing plant consist of 1 set Vibrating feeder, 1 set swing feeder, 1 set Jaw crusher, 1 set fine Jaw crusher, 1 set Vibrating screen, 1 set Ball mill, 1 set Spiral Classifier, 4 sets Conveyor belt, 2 sets Sand pump, 1 set Water pump, 16 ...